Production and Manufacturing Capacity

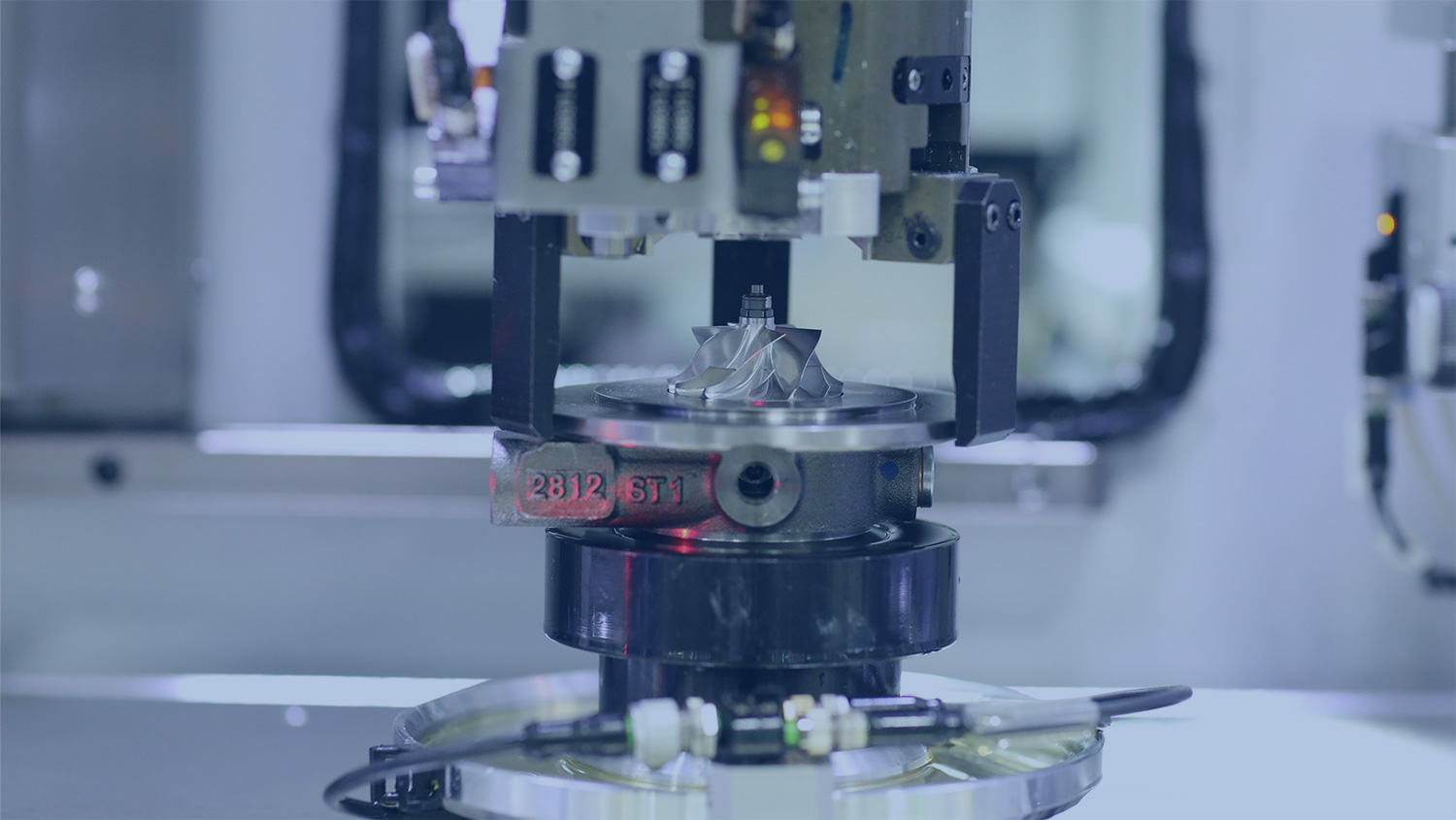

Weifu Tianli has a professional turbocharger production line with globally advanced turbocharger manufacturing equipment. Our intelligent equipment accounts for 85%, and the equipment networking rate reaches 100%. We have established a data integration platform with ERP, PLM, MES, and SCADA as the core, steadily promoting the company's intelligent development and continuously building an intelligent factory with Weifu Tianli characteristics.

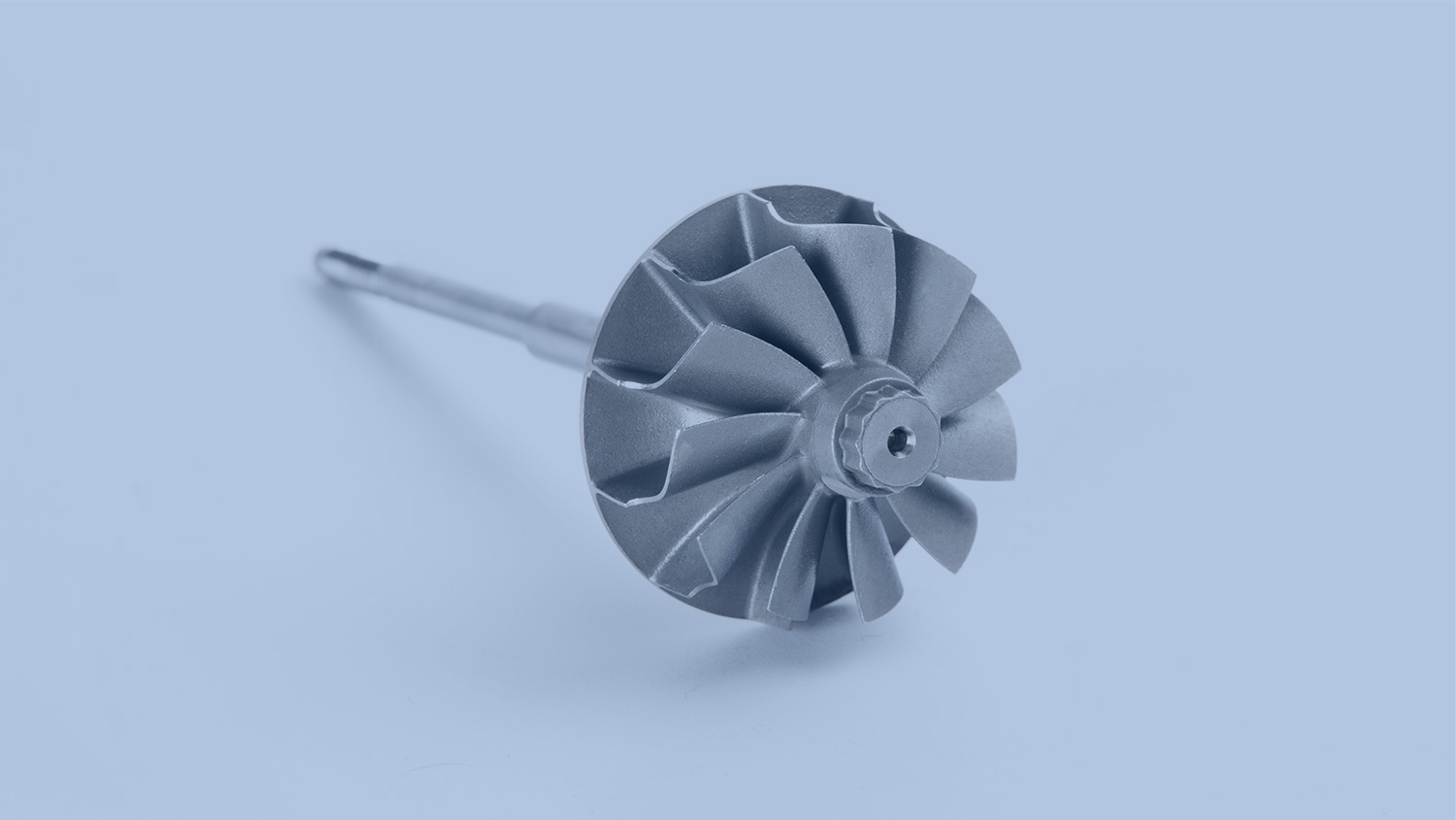

1.2 million

Shaft Machining Capacity

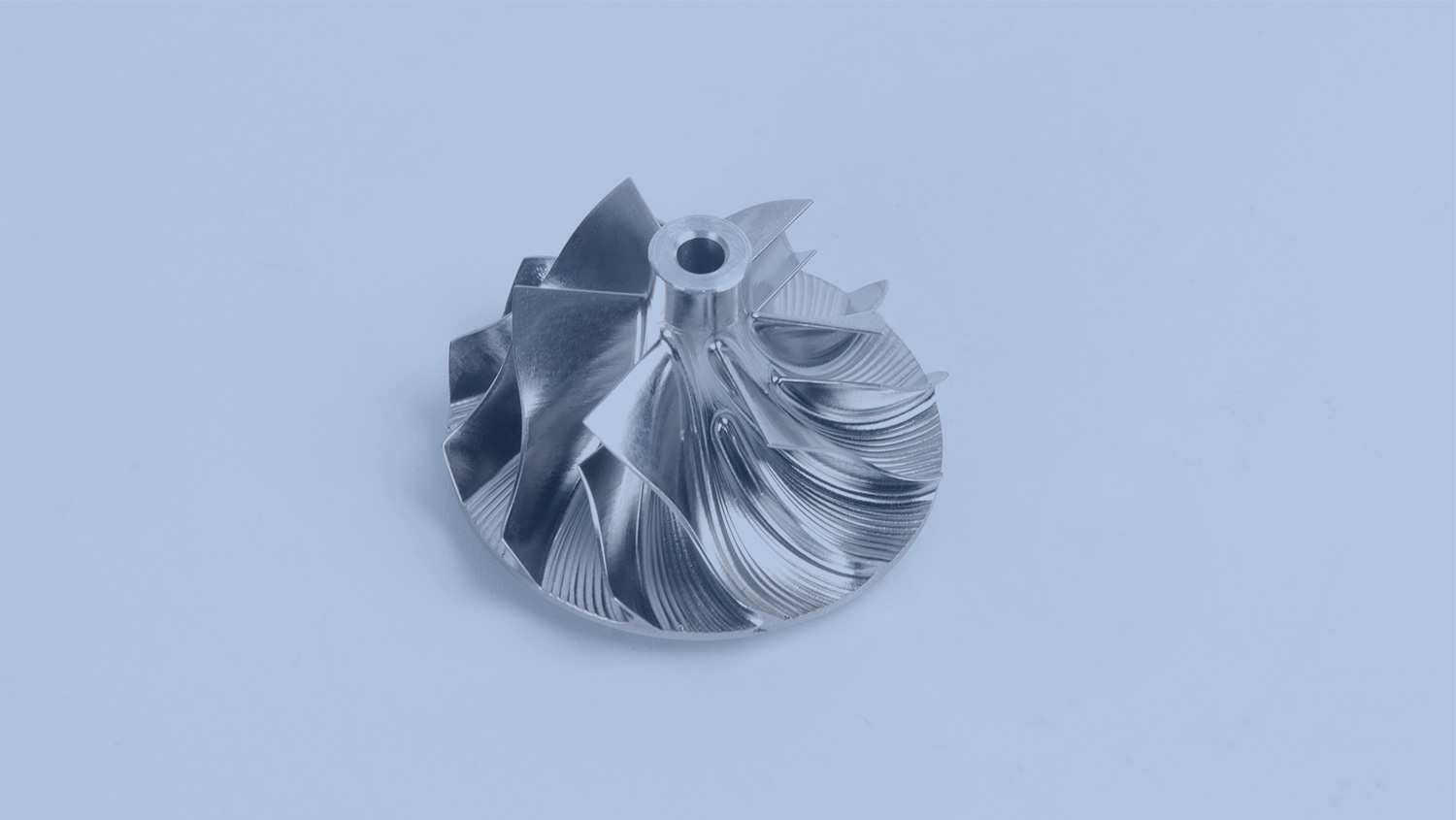

800,000

Impeller Machining Capacity

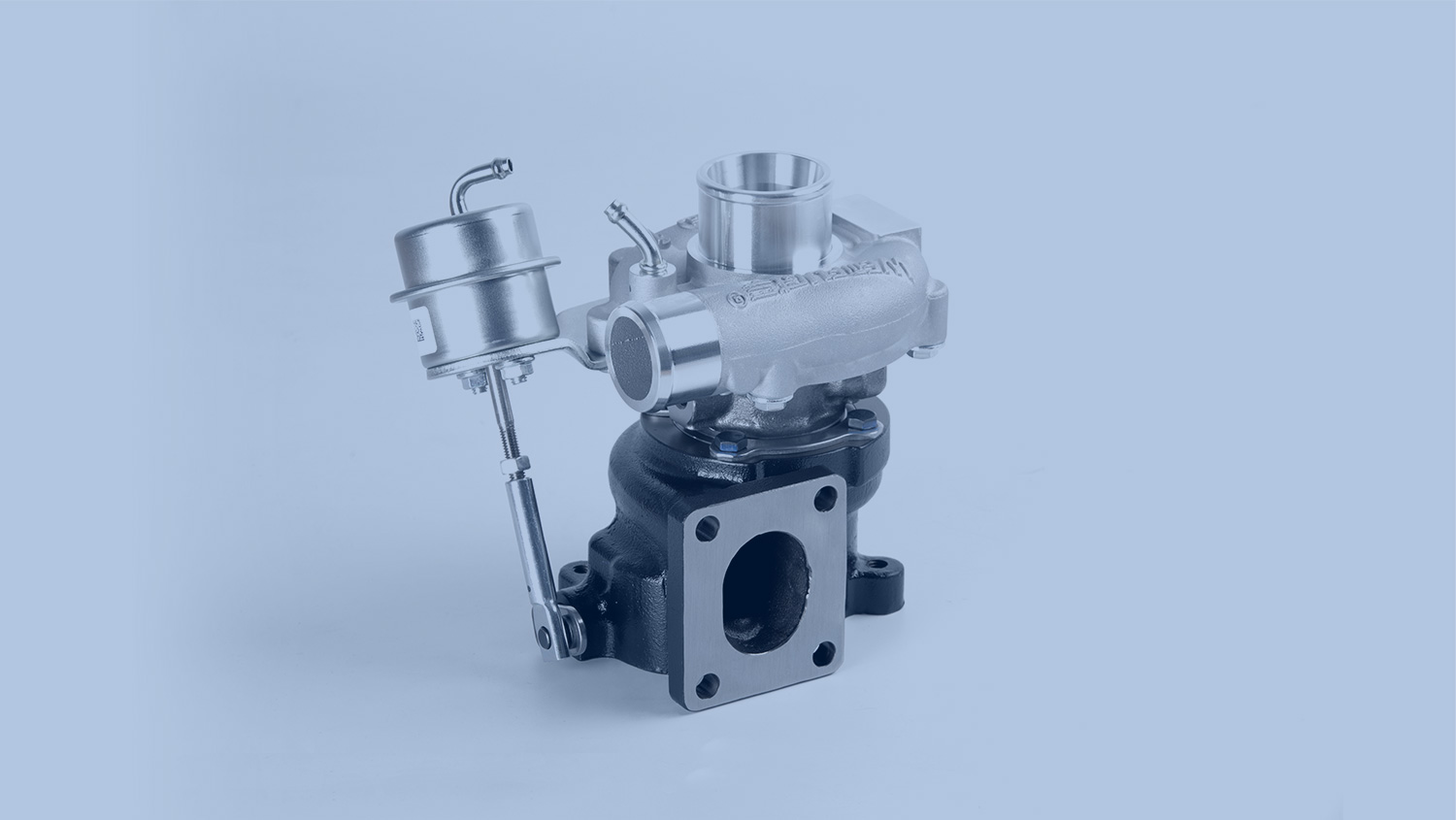

1.2 million

Assembly Line Capacity

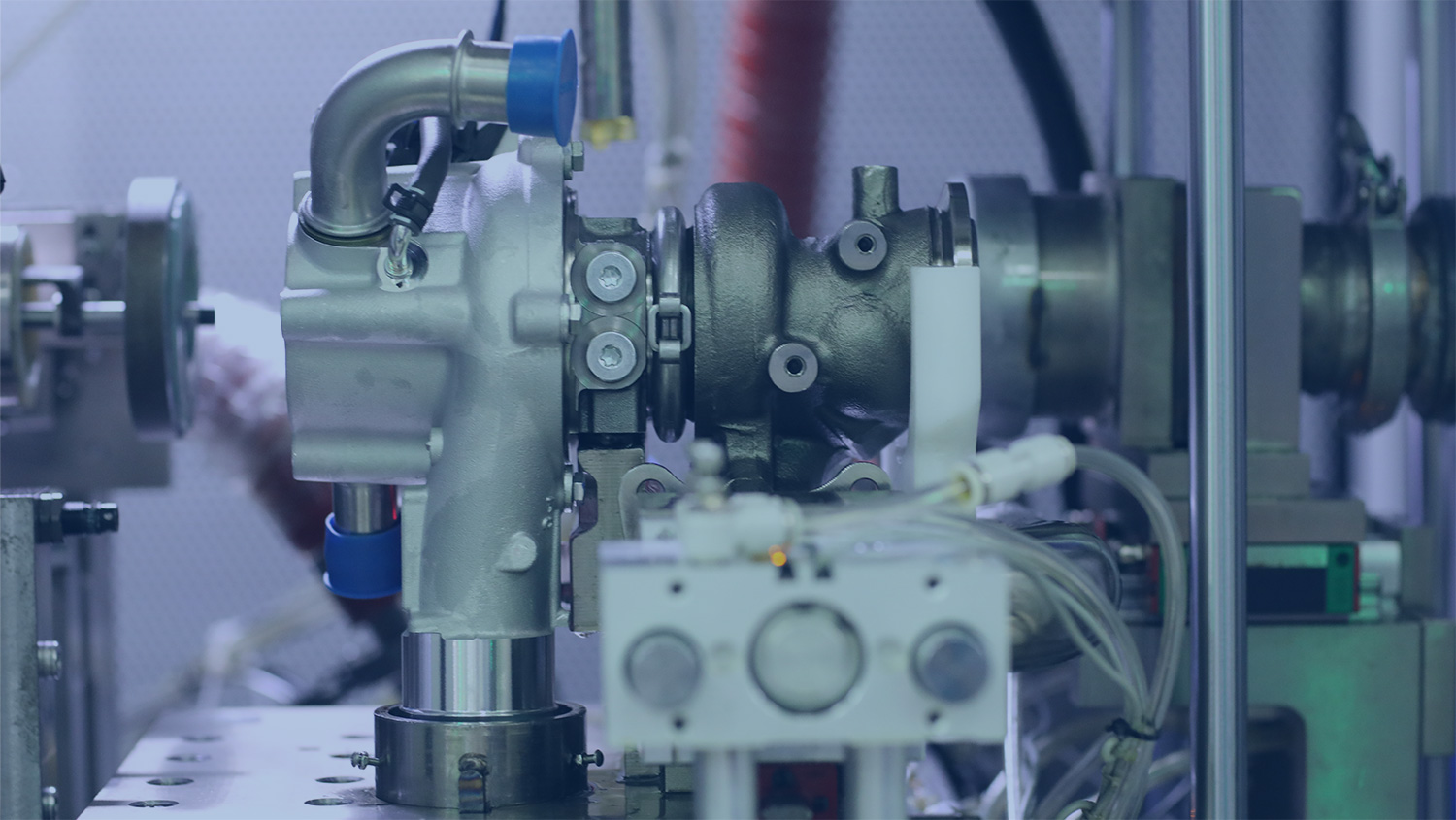

Production and Manufacturing Process

Weifu Tianli's production and manufacturing process first goes through the milling of impellers and turbine shafts in the machine workshop, producing the two core components of impellers and turbine shafts. The parts then move to the assembly workshop, where they go through three assembly processes: core assembly, dynamic balance testing, and assembly of the final product.

Quality Management

Weifu Tianli has introduced a data tracing and error prevention system. By scanning QR codes associated with each process, data can be collected and integrated to achieve data tracing and error prevention. Currently, 70 scanning points have been set up on the production line, and they will be promoted to all production lines in the future.